Atlas V Launches USSF-8

A United Launch Alliance (ULA) Atlas V rocket carrying the USSF-8 mission for the U.S. Space Force’s Space Systems Command lifted off on Jan. 21 at 2 p.m. EST from Space Launch Complex-41 at Cape Canaveral Space Force Station, Fla.

Launch Webcast

Live updates

To keep up to speed with updates to the launch countdown, dial the ULA launch hotline at 1-877-852-4321.

Join the conversation at Twitter, Facebook, Instagram and

LinkedIn

#AtlasV #USSF8

Mission Overview

A ULA Atlas V 511 rocket will launch the U.S. Space Force (USSF) - 8

mission for the U.S. Space Force’s Space Systems Command (SSC). USSF-8

will launch two identical Geosynchronous Space Situational Awareness

Program (GSSAP) satellites—GSSAP-5 and GSSAP-6—directly to a

near-geosynchronous orbit approximately 22,300 miles (36,000 km) above

the equator. Liftoff will occur from Space Launch Complex-41 at Cape

Canaveral Space Force Station, Fla.

GSSAP satellites are a

space-based capability operating in a near-geosynchronous orbit

supporting the U.S. Space Command space surveillance operations as a

dedicated Space Surveillance network (SSN) sensor. These satellites

provide neighborhood watch services in the Geosynchronous Earth Orbit

(GEO) improving flight safety for all spacefaring nations operating in

that orbit. Enhanced position knowledge of satellites at that distance

improves the ability to warn a spacecraft owner/operator if there is

another object anticipated to approach too closely and create a

hazardous situation.

Data from the GSSAP will uniquely

contribute to timely and accurate orbital predictions, enhancing our

knowledge of the GEO environment and further enabling space flight

safety including satellite collision avoidance.

Unique to this

mission is the first and only planned flight of the Atlas V 511

configuration. The 511 is the only unflown configuration in the Atlas

family.

Launch Vehicle

Payload Fairing (PLF)

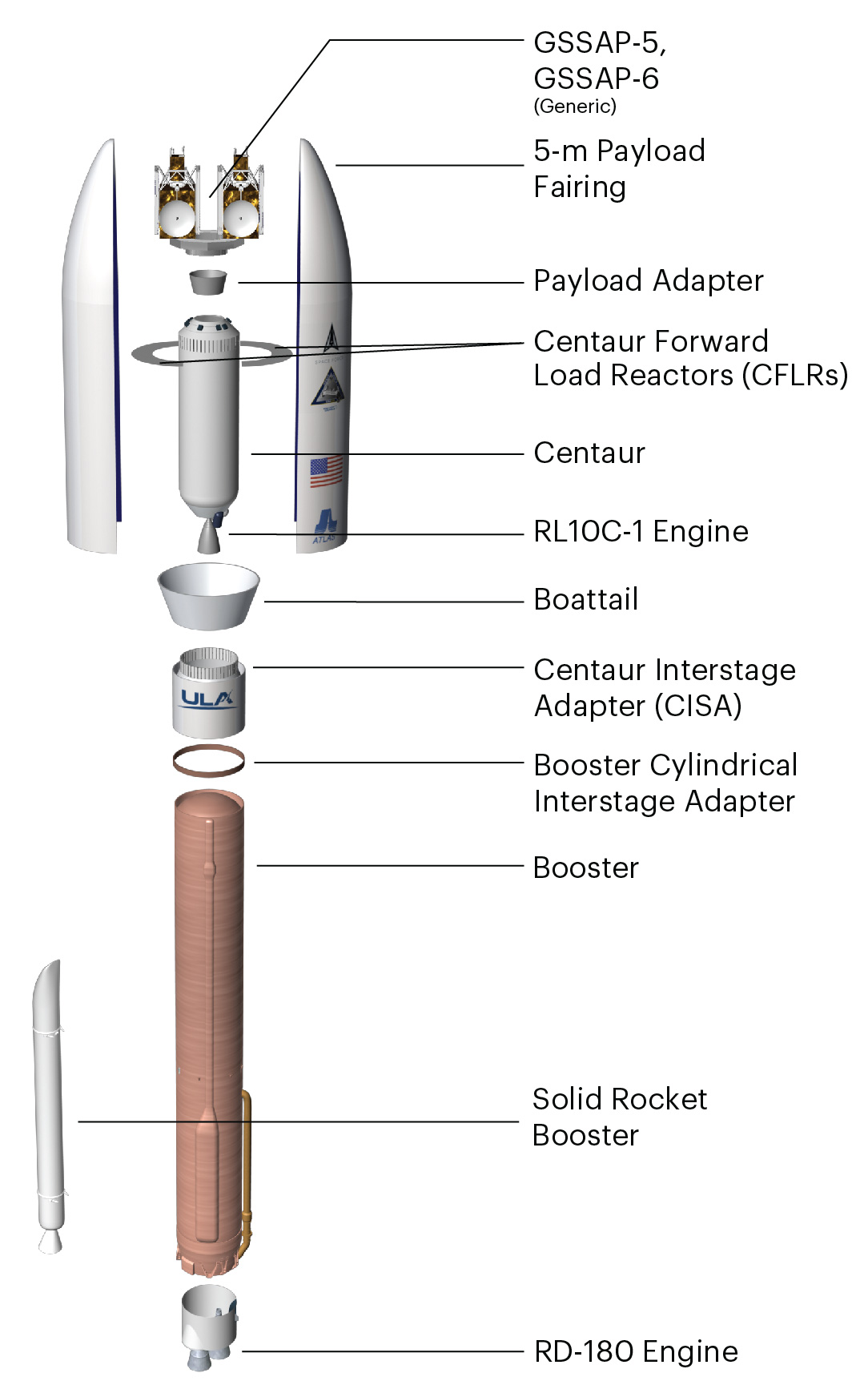

The spacecraft is encapsulated in a 17-ft (5-m) diameter short payload fairing. The 5-m PLF is a sandwich composite structure made with a vented aluminum-honeycomb core and graphite-epoxy face sheets. The bisector (two-piece shell) PLF encapsulates both the Centaur and the satellite. The vehicle’s height with the 5-meter short PLF is approximately 196 ft (59.7 m).

Centaur

The Centaur second stage is 10 ft (3 m) in diameter and 41.5 ft (12.6 m) in length. Its propellant tanks are pressure-stabilized and constructed of corrosion-resistant stainless steel. Centaur is a cryogenic vehicle, fueled with liquid hydrogen and liquid oxygen, powered by an RL10C-1 engine producing 22,900 lbs (101.8 kilo-Newtons) of thrust. The cryogenic tanks are insulated with a combination of helium-purged blankets, radiation shields and spray-on foam insulation (SOFI). The Centaur forward adapter (CFA) provides structural mountings for the fault-tolerant avionics system and structural and electrical interfaces with the spacecraft.

Booster

The booster is 12.5 ft (3.8 m) in diameter and 106.5 ft (32.5 m) in length. The booster’s tanks are structurally rigid and constructed of isogrid aluminum barrels, spun-formed aluminum domes and intertank skirts. Booster propulsion is provided by the RD-180 engine system (a single engine with two thrust chambers). The RD-180 burns RP-1 (Rocket Propellant-1 or highly purified kerosene) and liquid oxygen and delivers 860,200 lbs (3.83 mega-Newtons) of thrust at sea level. One solid rocket booster (SRB) generates the additional power required at liftoff, providing 371,550 lbs (1.6 mega-Newtons) of thrust. The Centaur avionics system, provides guidance, flight control and vehicle sequencing functions during the booster and Centaur phases of flight.

Flight Profile

Space Launch Complex-41 // Processing

Space Launch Complex-41, the East Coast home of the Atlas V rocket at Cape Canaveral Space Force Station in Florida, employs a “clean pad” concept of operations to ready launch vehicles and payloads for ascent into space. The rocket elements are assembled atop a Mobile Launch Platform inside the Vertical Integration Facility (VIF) located adjacent to the launch pad. The platform and fully stacked Atlas V then travels by rail approximately 1,800 feet northward from the VIF to the pad for the final countdown, fueling and liftoff. Complex 41 was constructed by the U.S. Air Force in the 1960s for the Titan rocket program. The site was rejuvenated in support of the Atlas V starting in the late 1990s.

1. Atlas Spaceflight Operations Center (ASOC)

Launch Control Center

Mission Director’s Center,

Mission Support Teams,

Launch Vehicle Horizontal Processing &

Ordnance Installation

2. Delta Operations Center

Offline Vertical Integration (OVI):

Interstage Adapters, Centaur,

Boattail, Base Module & Centaur

Forward Load Reactor Deck

3. Spaceflight Processing Facility

Spacecraft Processing,

Testing & Encapsulation

4. Vertical Integration Facility

Launch Vehicle Integration &

Testing, Spacecraft Mate &

Integrated Operations

Production

1. Promontory, UT

Solid Rocket Booster Fabrication

at Northrop Grumman

2. Denver, CO

ULA Headquarters &

Design Center Engineering

3. Harlingen, TX

Payload Adapter,

Booster Adapter &

Centaur Adapter Fabrication

4. Decatur, AL

Booster Fabrication & Final Assembly,

Centaur Tank Fabrication & Final Assembly

5. West Palm Beach, FL

RL10C-1 Engine Fabrication at

Aerojet Rocketdyne

6. Khimki, Russia

RD-180 Engine Fabrication at

NPO Energomash

7. Zurich, Switzerland

5-m Payload Fairing

Fabrication at RUAG Space