Atlas V Launches Landsat 9

A United Launch Alliance (ULA) Atlas V rocket carrying the Landsat 9 mission for NASA lifted off on Sept. 27 at 11:12 a.m. PDT from Space Launch Complex-3 at Vandenberg Space Force Base. To date ULA has launched 145 times with 100 percent mission success.

Launch Webcast

Mission Overview

For nearly 50 years, Landsat satellites have provided the longest continuous global record of Earth’s changing landscapes. With Landsat 9, the mission will continue collecting essential science-quality data on Earth’s forests, farms, cities and freshwater regions. Landsat 9 will join Landsat 8 in orbit, and the two satellites together will collect images of our planet’s landscapes and coastal regions every eight days. Landsat is the only U.S. satellite system designed and operated to repeatedly observe the global land surface at a moderate scale to show both natural and human-induced change.

Landsat 9 is a joint mission of NASA and the U.S. Geological Survey (USGS). NASA’s Goddard Spaceflight Center manages the mission through launch and post launch checkout and the Launch Services Program based at Kennedy Space Center manages the launch service. USGS operates the satellite and the mission data archive.

In addition to Landsat 9, this mission includes the Landsat 9 ESPA Flight System (EFS) which will deploy multiple CubeSats after Landsat 9 separation. The EFS is a U.S. Space Force activity to demonstrate the capability of integrating and delivering secondary payloads to orbit on an adapter ring. There are four multi-manifest satellites sponsored by the Defense Innovation Unit, Air Force Research Laboratory, Missile Defense Agency and NASA. The NASA CubeSats include the Colorado Ultraviolet Transit Experiment (CUTE) from the University of Colorado at Boulder which will measure how near-ultraviolet light from a host star changes when an exoplanet passes in front of it and through a planet’s atmosphere. The Cusp Plasma Imaging Detector (CuPID) from Boston University will measure X-rays emitted when solar wind plasma collides with neutral atoms in Earth’s atmosphere.

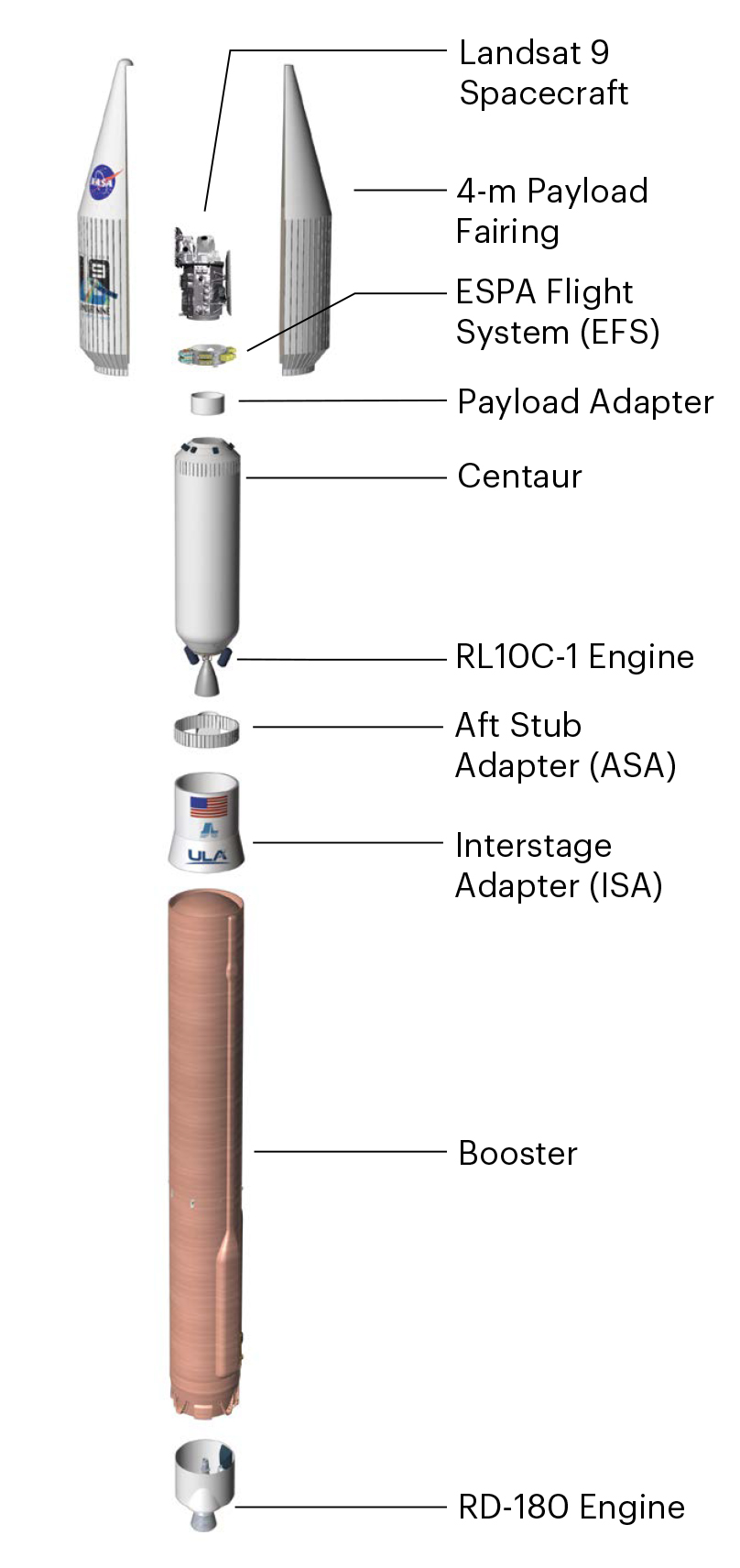

Launch Vehicle

Payload Fairing (PLF)

The spacecraft is encapsulated in the 14-ft (4-m) diameter extra extended payload fairing (XEPF). The XEPF is a bisector (two-piece shell) fairing consisting of aluminum skin/stringer construction with vertical split-line longerons. The vehicle’s height with the PLF is approximately 194 ft (59.1 m).

Centaur

The Centaur second stage is 10 ft (3 m) in diameter and 41.5 ft (12.6 m) in length. Its propellant tanks are pressure-stabilized and constructed of corrosion-resistant stainless steel. Centaur is a cryogenic vehicle, fueled with liquid hydrogen and liquid oxygen, powered by an RL10C-1 engine producing 22,900 lbs (101.8 kilo-Newtons) of thrust. The cryogenic tanks are insulated with a combination of helium-purged blankets, radiation shields and spray-on foam insulation (SOFI). The Centaur forward adapter (CFA) provides structural mountings for the fault-tolerant avionics system and structural and electrical interfaces with the spacecraft.

Booster

The booster is 12.5 ft (3.8 m) in diameter and 106.5 ft (32.5 m) in length. The booster’s tanks are structurally rigid and constructed of isogrid aluminum barrels, spun-formed aluminum domes and intertank skirts. Booster propulsion is provided by the RD-180 engine system (a single engine with two thrust chambers). The RD-180 burns RP-1 (Rocket Propellant-1 or highly purified kerosene) and liquid oxygen and delivers 860,200 lbs (3.83 mega-Newtons) of thrust at sea level. The Centaur avionics system, provides guidance, flight control and vehicle sequencing functions during the booster and Centaur phases of flight.

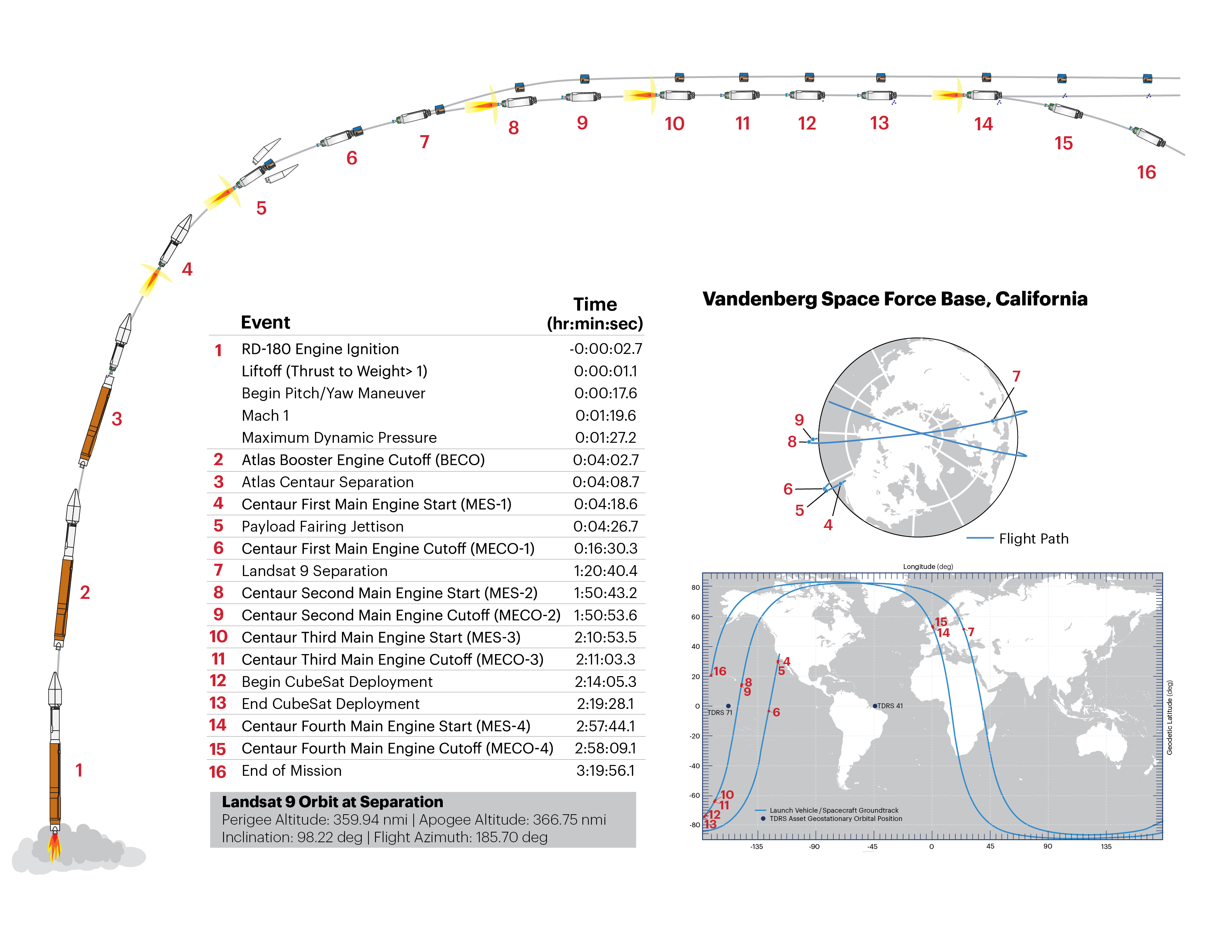

Flight Profile

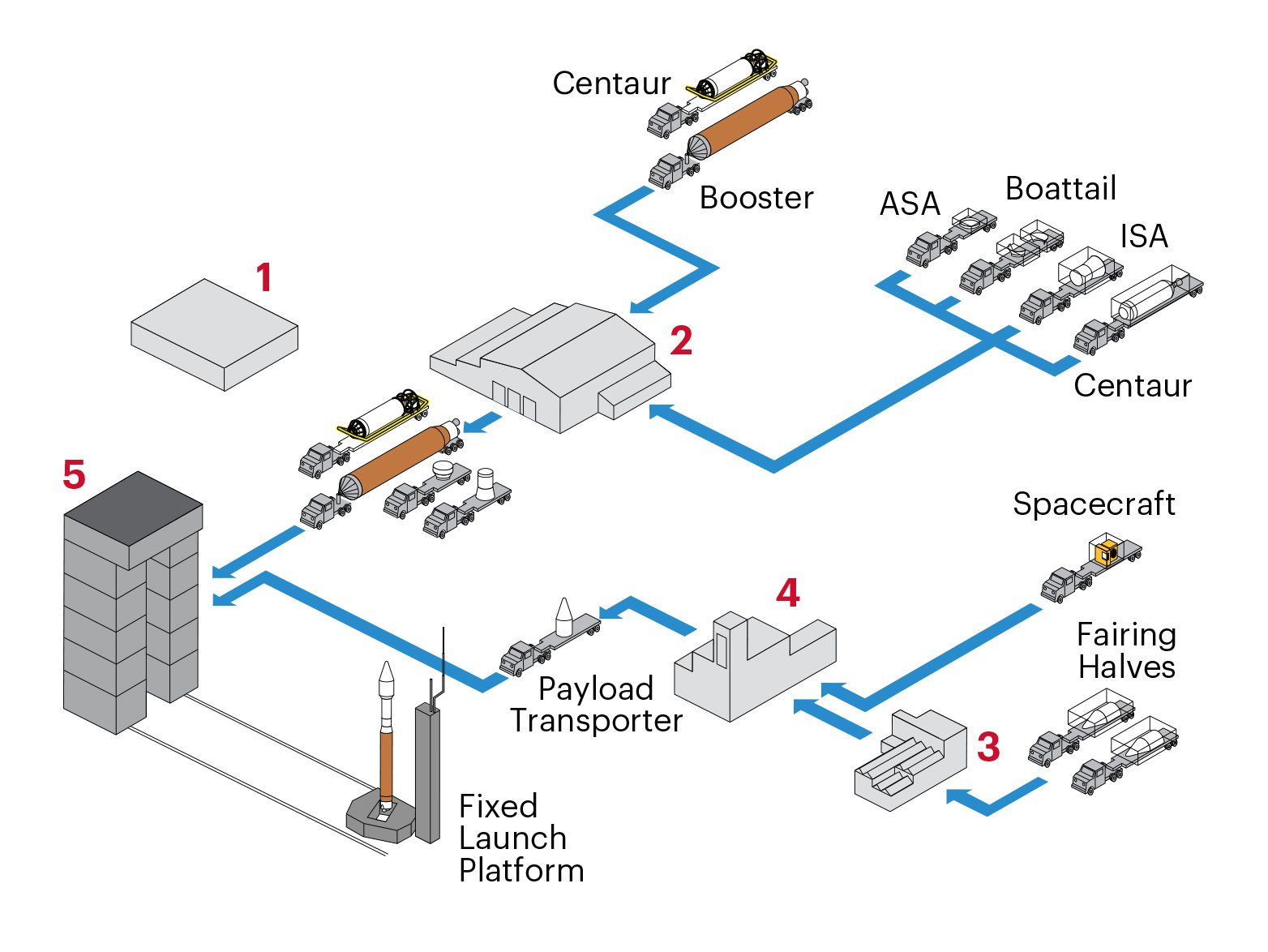

Space Launch Complex-3 // Processing

Space Launch Complex-3 (SLC-3) is ULA's West Coast launch pad for the Atlas V rocket. In contrast to Atlas V operations at Cape Canaveral, at SLC-3 launch vehicle integration and testing, spacecraft mate and integrated operations happen in the Mobile Service Tower (MST). A few hours before launch, we roll the MST to its park position approximately 250 feet southeast of the rocket.

1. Remote Launch Control Center (RLCC)

Launch Control Center &

Mission Director's Center

2. Operations Center

Receiving & Inspection

3. Building 8337

PLF/Adapter Receiving & Inspection

4. Spacecraft Processing Facility

Spacecraft Processing, Testing &

Encapsulation

5. Mobile Service Tower

Launch Vehicle Integration & Testing,

Spacecraft Mate & Integrated Operations

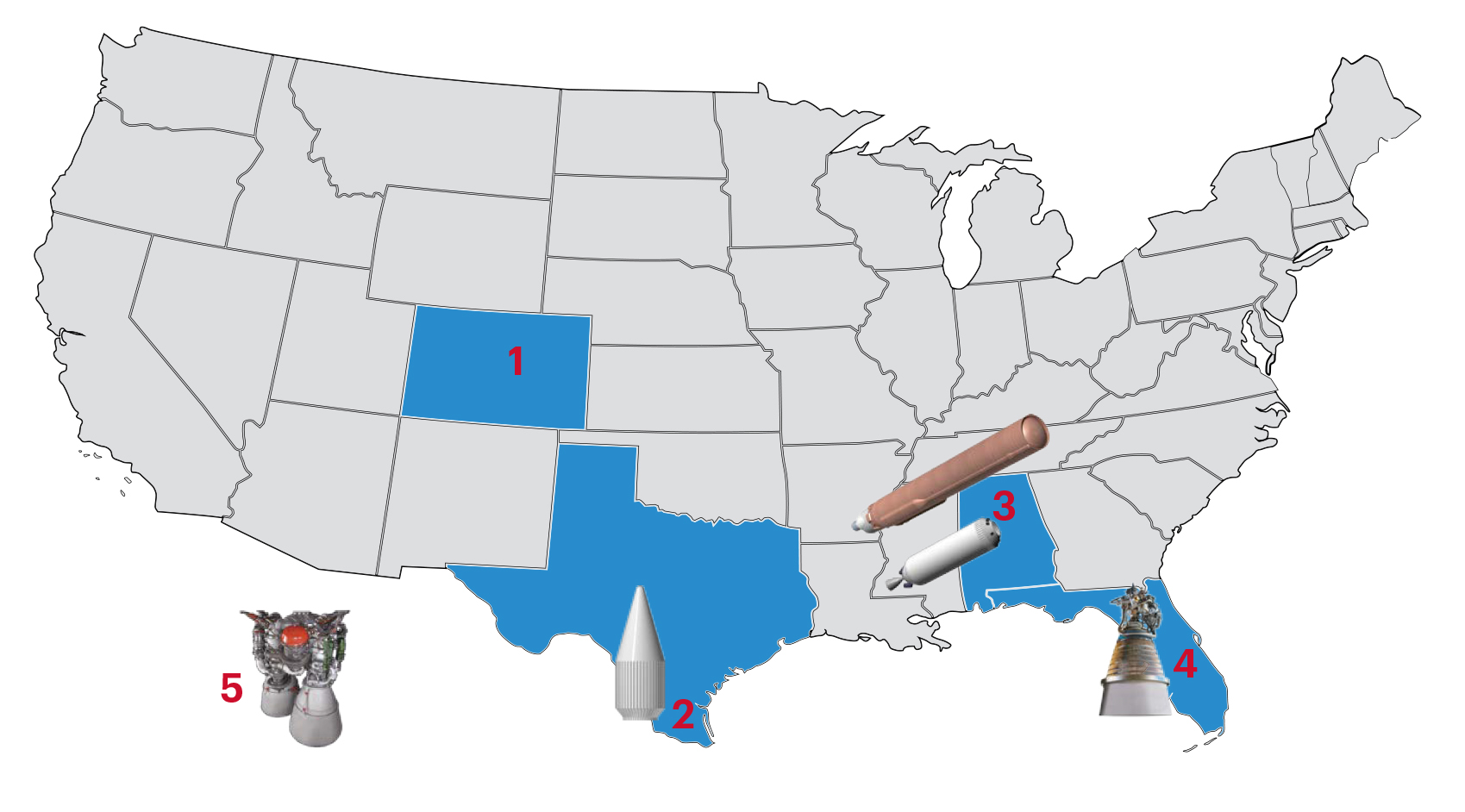

Production

1. Denver, CO

ULA Headquarters &

Design Center Engineering

2. Harlingen, TX

Payload Fairing,

Payload Fairing Adapter,

Booster Adapter &

Centaur Adapter Fabrication

3. Decatur, AL

Booster Fabrication

& Final Assembly,

Centaur Tank Fabrication &

Centaur Final Assembly

4. West Palm Beach, FL

RL10C1 Engine Fabrication at

Aerojet Rocketdyne

5. Khimki, Russia

RD180 Engine Fabrication at

NPO Energomash